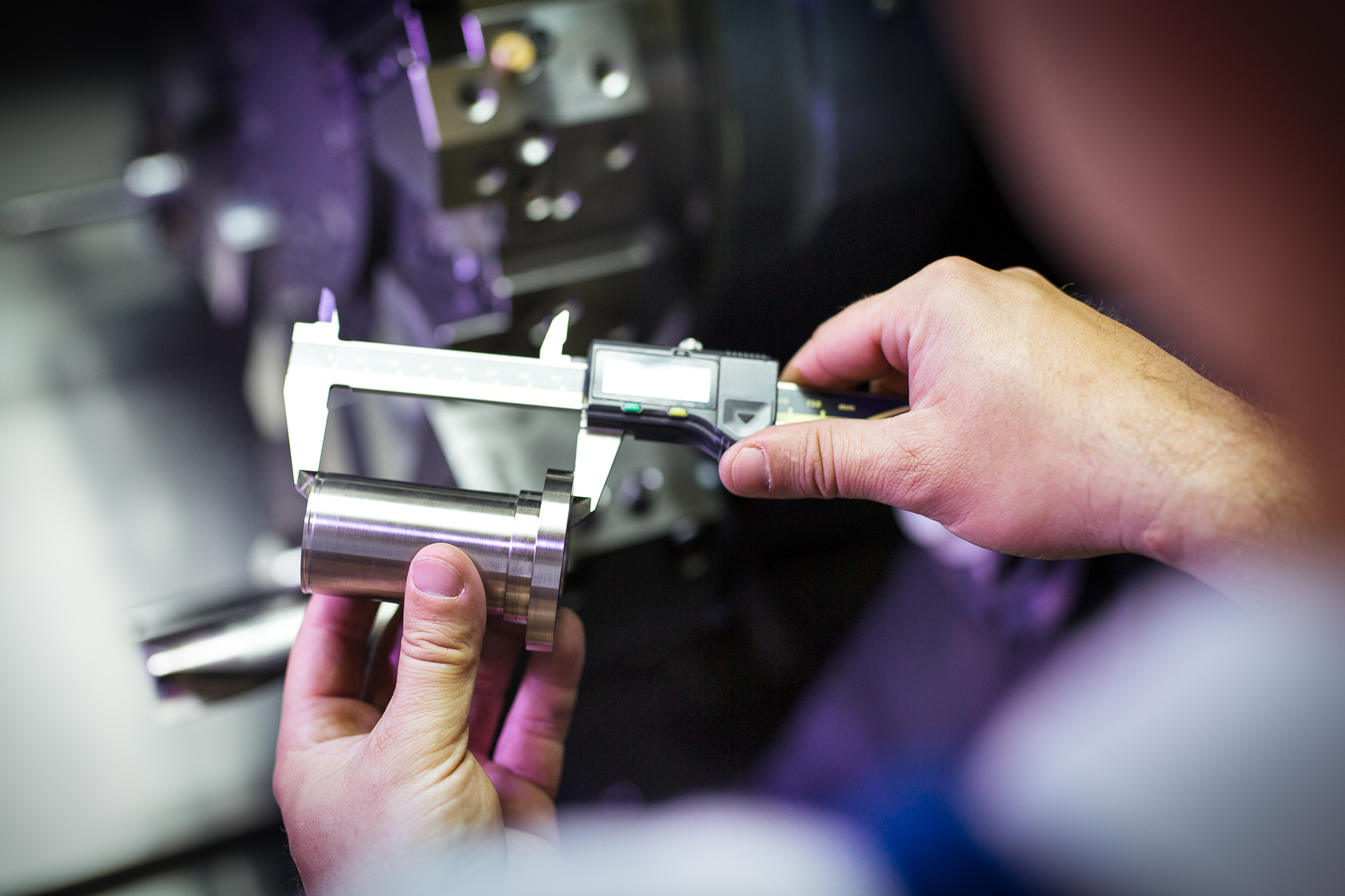

RV Industrials maintains a systematic approach that emphasizes quality at every stage of CNC machining. We ensure that parts that are produced in our machining centers conform to the standards and requirements of our customers.

Even though CNC is a high precision machining process, we monitor our performance against the established objectives and improve our quality control.

Our CNC machining services combine thoroughness, accuracy, and repeatabilityand ensuremachining precision to the level of± 0 .002microns, empowered by the 5-axis machine setup.

We have a team of well-experienced machinists who check out each of the details of tolerance and machine parts that precisely match customers’CAD drawings and requirements.